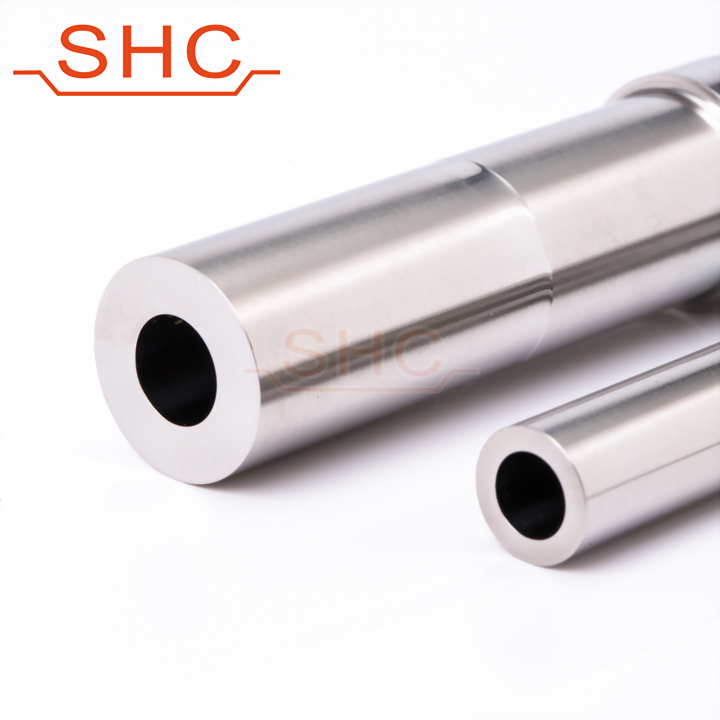

Round carbide punch pin tooling

●Various types of Punches and Pins●Forming , extrusion and ejector tooling●Tungsten carbide , tungsten Carbide tipped and tool Steel●TiN , TiCN and TiAlN surface coating●Surface roughness can be achieved Ra 0.015

Product:

- EDM products

- 6 Lobes / 12 point punch

- Carbide Punch

- Trimming Die

- Customized and irregular punches

Material: 1. HSS: -1.3343=SKH51=BM2 -1.3243=SKH55=BM35 -1.3247=SKH59=BM42 -ASP30 -ASP60 2. Die steel: -1.2379=SKD11=BD2 -1.2344=SKD61=BH13 3. Carbide

Advantage of tungsten carbide

The primary advantage of tungsten carbide is its strength. Carbide dies which are notable for offering more satisfactory performance than their steel counterparts, tend to last significantly longer, too. The tungsten carbide dies require replacement much less often than typical steel dies, which not only reduces overall maintenance costs, but machine downtime as well.